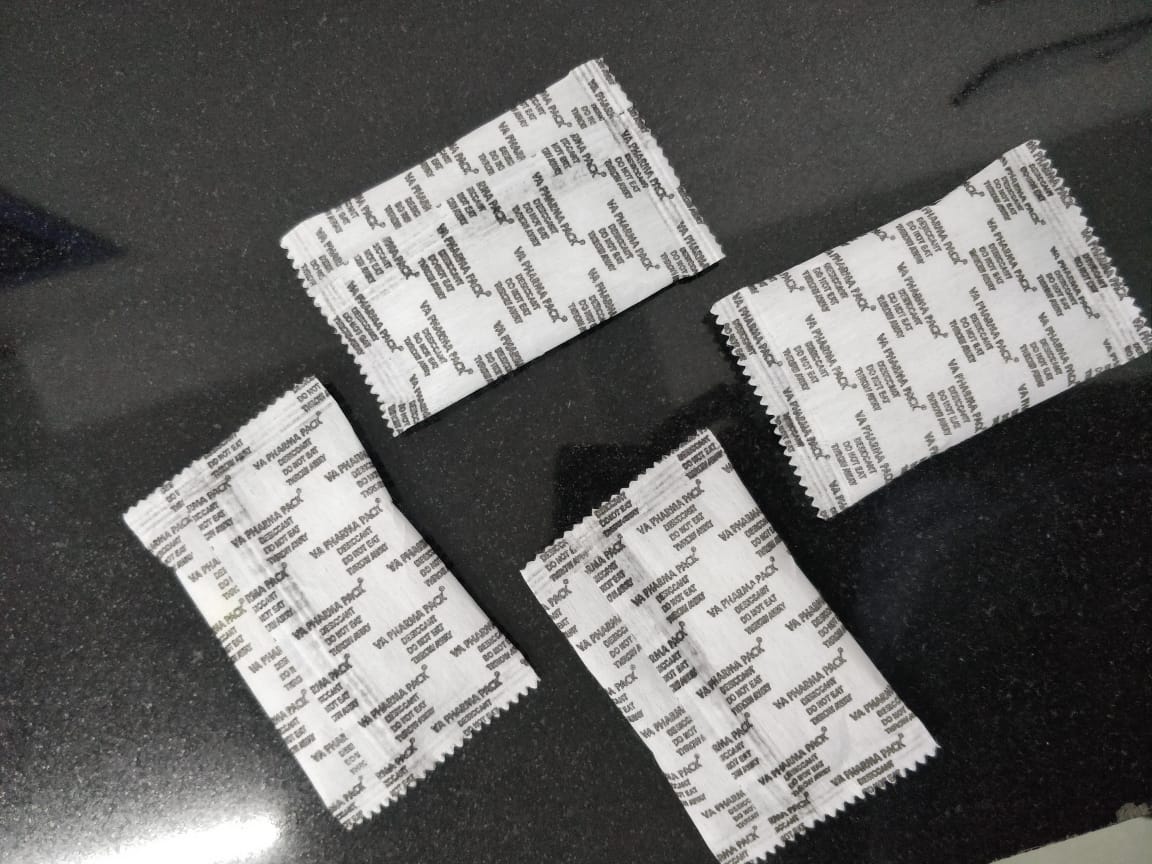

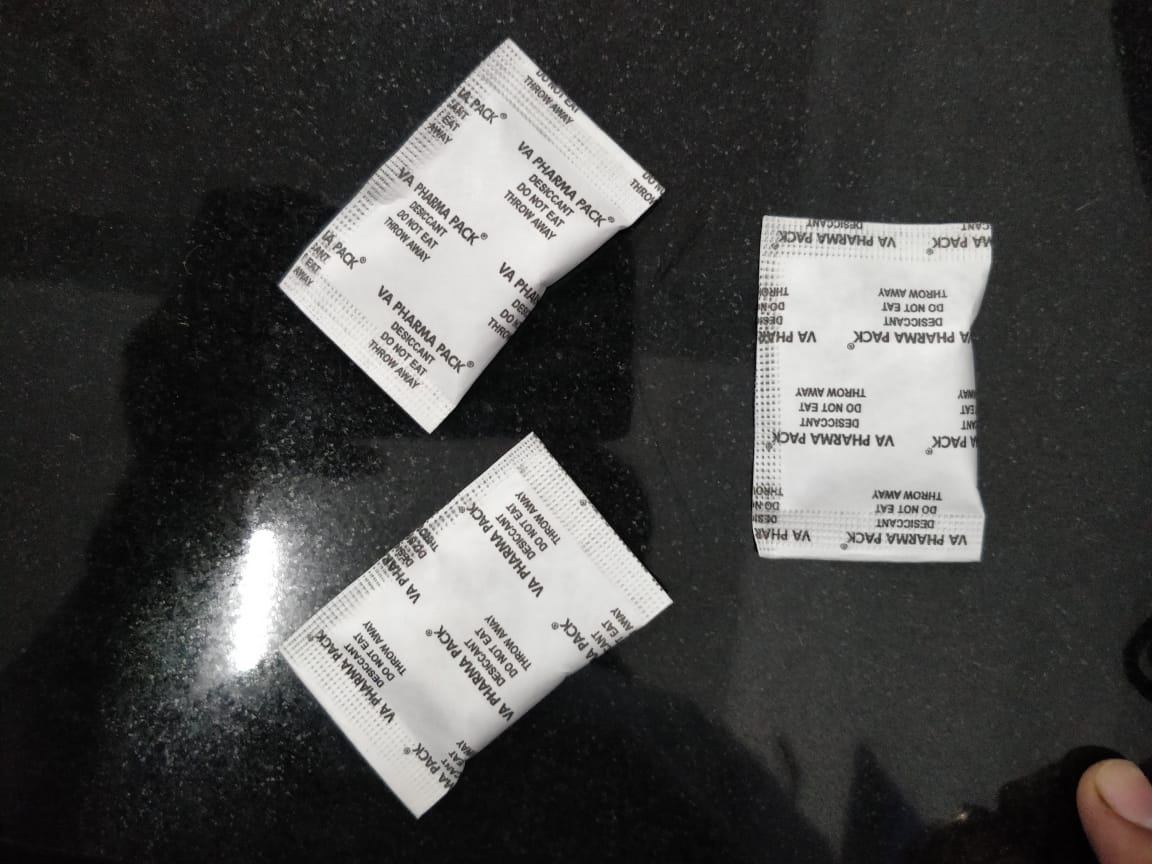

We have capability to manufacture Cargo Desiccant Bag in 4 form:

Desiccant is a drying agent that is used to absorb moisture from the air inside moisture barrier bags. Desiccant absorbs moisture vapor (humidity) from the air left inside the barrier bag after it has been sealed. Any moisture that penetrates the bag will also be absorbed. Desiccant remains dry to the touch even when it is fully saturated with moisture vapor.

How much Desiccant do I need?Desiccant is sold by the “Unit” or fractional Unit, or in grams. One unit of desiccant will absorb a specific amount of moisture. A unit weighs about 33 grams. There are several standards for calculating the desiccant loading for bags. Each standard is for a specific application, and requires different amounts of desiccant for the same bag size. Once you determine which standard is correct for your dry packing application, apply these formula, or go to www.StaticControl.com and select the Desiccant Calculator.

Certain kinds of electronic devices called “Surface Mount Devices” or SMD’s are mounted on a circuit card by high temperature soldering. The body of the SMD is made from plastic that absorbs moisture from the air. When the case is heated during soldering, the moisture inside turns to steam, and may break the device as the steam escapes. Keeping SMD’s dry before soldering means that the devices will not be damaged.