Container Sweat and Condensation Issues

Condensation Issues in Organic Commodities

-

Organic and/or agricultural products retain considerable

intrinsic moisture content.

-

Considered hygroscopic cargoes which are in equilibrium

with the air in the container and can emit as well as absorb

moisture.

-

The amount of water available within a container of such

cargoes is usually much higher than containers loaded

with manufactured inorganic product.

-

Hygroscopic cargoes change temperature comparatively

slowly. Thus, when a container is shipped across climatic

zones, the cargo adjusts to the changing ambient

temperatures much more slowly than the container walls

and the air. This delay can cause considerable temperature

differences within the container; these are a major driving

force for moisture translocation and condensation.

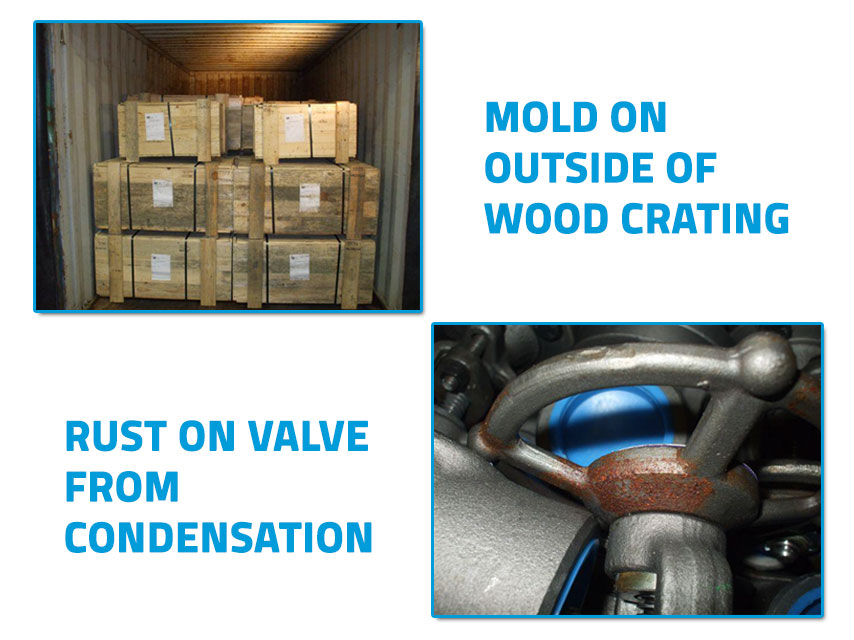

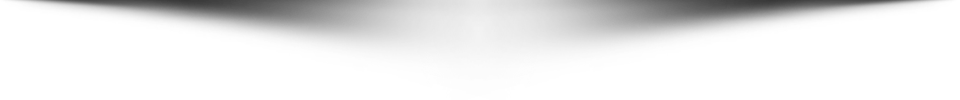

Condensation Issues in Non-Organic Commodities

-

Cargoes which are entirely dry and do not contain measurable levels of

moisture, e.g. pure metal products and/or machinery without corrosion

protection or surface treatment

-

Extreme variances in relative humidity and dew points causing

condensation can have as damaging effect commercially as those which

are otherwise in equilibrium such as in the case of organic product.

-

A good example of an inorganic commodity presenting a high

susceptibility to condensation is steel cargoes. The main sources of

condensation damage to steel are condensation water generated by the

conveyance, intermodal container or other means of transport, the cargo

itself and within the packaging (particularly hygroscopic packaging

materials). Steel cargos require low humidity/moisture conditions and

possibly forced ventilation to minimize the condensation risk.

-

Also unsuitable means of transport such as vessels having poor hatch

covers or with inadequate ventilation means, damaged containers,

uncovered railroad freight cars and trucks, incorrect storage in the open,

use of unsuitable tarpaulins, exposed loading in wet weather conditions,

and variations in temperature and climatic conditions during long

voyages may result in rust damage.

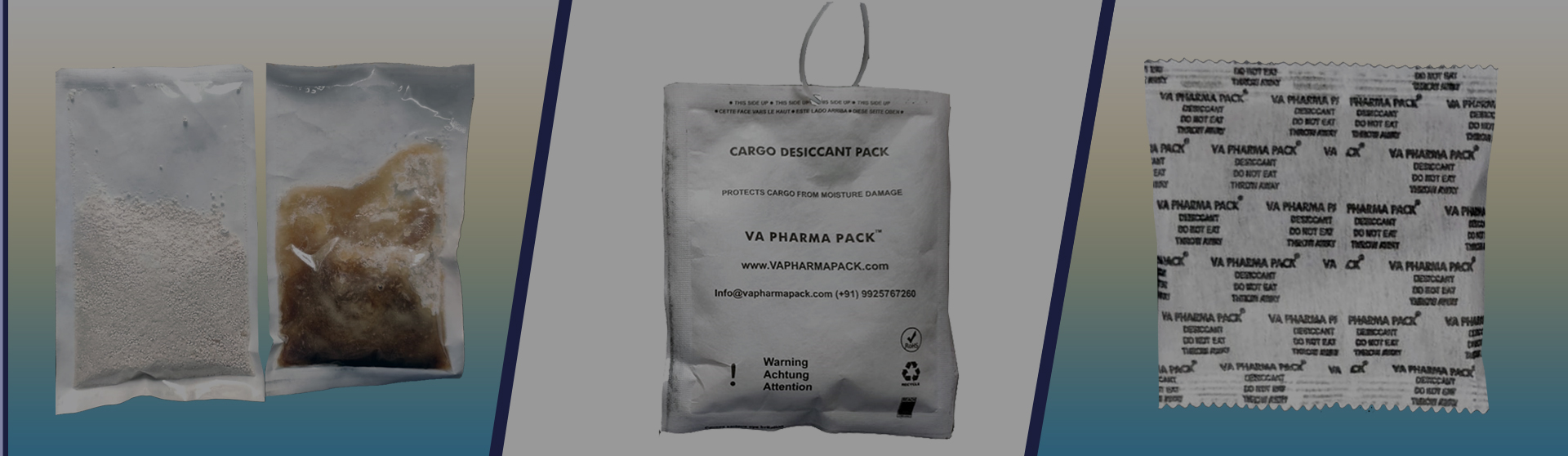

Type Of Desiccants

-

Montmorillonite Clay

-

Silica Gel (SiO2 * H2O)

-

Molecular Sieve (Synthetic Zeolite - Na12Al03SiO2 12XH2O)

-

Calcium Sulfate (CaSO4)

-

Calcium Sulfate (CaSO4)

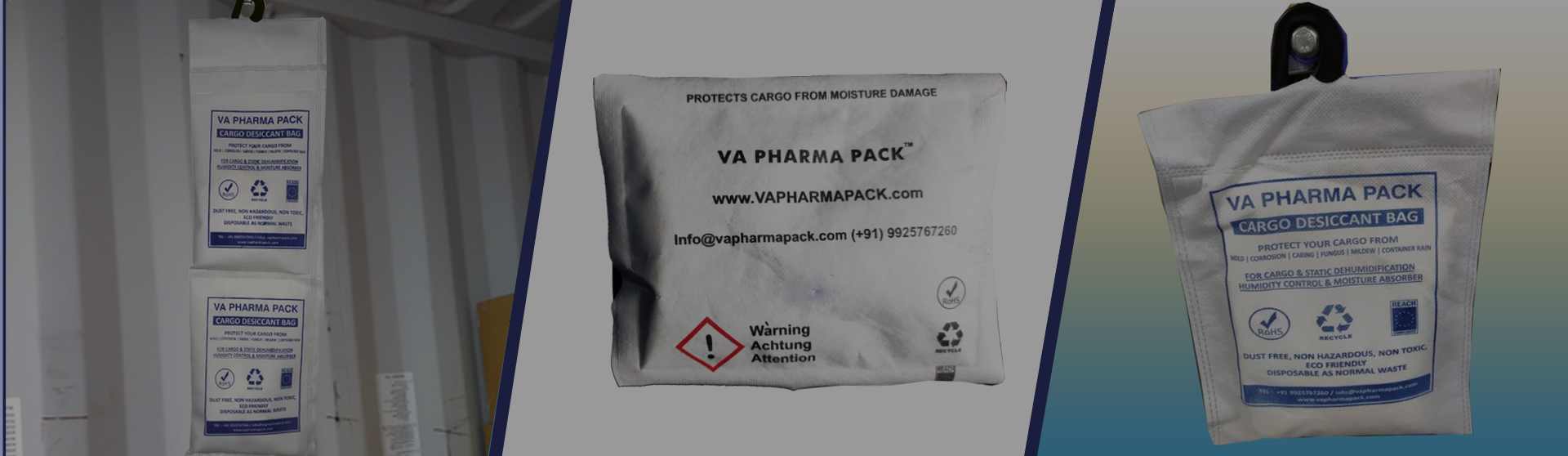

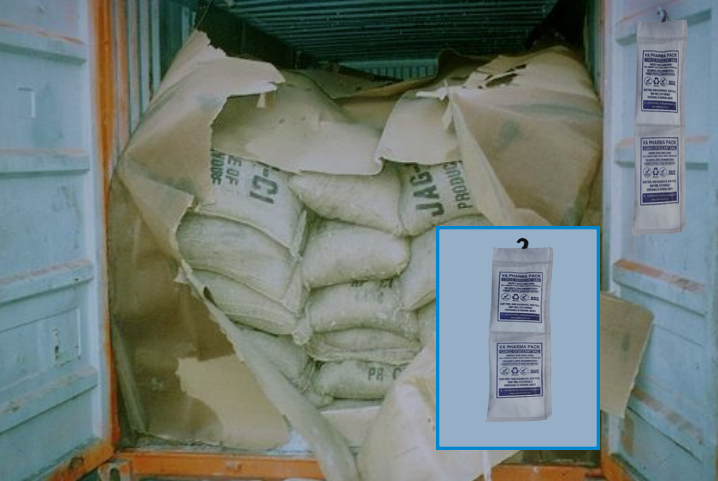

Application of Desiccants

-

Place desiccants throughout the stow during

loading, unfilled header areas and more at the

rear after completion of loading. Since desiccants

absorb moisture as soon as they are exposed to

air, they should be kept in original packaging

until ready for use.

-

Appropriate use of desiccant bags or strips (a

rule of thumb = 32 one-pound bags of desiccant

for a 20-foot container for a typical 30-40day

overseas voyage) depending on the following:

length of voyage, stowage during voyage: deck or

below deck.

How Desiccants Work

-

Most porous adsorbents, such as silica gel, activated clay or molecular sieves rely

upon physical adsorption rather than chemical adsorption to accomplish their

function.

-

Physical adsorption involves relatively weak intermolecular forces (van der Waals

forces and electrostatic interactions) between the moisture and surface of the

desiccant.

-

Chemisorbents, such as calcium oxide, involve an actual chemical bond. Physical

adsorption of moisture is typically exothermic. The strength of the adsorptive

bonds can thus be measured by the heat of adsorption. The higher the heat of

adsorption for moisture on the desiccant, the stronger the bonding and the less

easily that moisture can be subsequently removed.

-

In a porous desiccant such as the silica gel used by Dri-Box, water is removed

from the airspace by multi-layer adsorption, which is the attraction of thin layers

of water molecules to the surface of the desiccant. Because the desiccant is very

porous, the surface area is high and significant amounts of water can be attracted

and adsorbed;

-

By capillary condensation in which the smaller pores become filled with water.

Capillary condensation occurs because the saturation water vapor pressure in a

small pore is reduced by the effect of surface tension.

Container Stuffing (Pre / Post Completion)

-

Apply suitable dunnage to separate the cargo from the container’s walls and

floors. This cannot prevent the formation of condensation, but can

significantly reduce its commercial implications.

-

Kraft paper or similar material to line the walls and floors of containers or as

protective sheets on top of the cargo. Serves to absorb small amounts of

condensation and in some circumstances prevent or reduce staining and

similar damage.

-

All wooden packaging, skids and dunnage must be dry. Moisture content

should be less than 18%. Particular attention to the container floor is

necessary. The humidity of the wood should not be above 18%. The use of

de-humidifiers can be beneficial in very special cases to ensure a dry

container is presented for loading.

-

Use of handheld devices (moisture meter) as a cost effective means to

validating moisture monitoring process.

-

Storage of pallets in dry environment.

-

Consider the insertion of temperature and humidity indicators inside the

container to monitor internal container conditions during transit.

-

Use the results of the monitored shipments to gauge the amount of

desiccant/protection required for future shipments based on cargo and

transit lanes

Transit Issues

-

Minimize Radiation of heat at Terminals and On board Ship

-

Where possible cargoes sensitive to condensation must be

protected from the extremes of radiant heat and extreme

cold

-

Terminal stack : shaded stow required.

-

Aboard ship:under deck stow or protected inner block deck stow required.

-

Stowage Considerations:Heat sources( Bunker tanks,

engine compartments)

-

At destination, advance delivery notification is important

to enable delivery to be carried out for

sensitive/hygroscopic cargoes arriving at terminals with

near zero temperatures. In such cases the cargo can

experience what "cold shock" of first night ashore.