Moisture is one of the most critical factors influencing aflatoxin contamination in peanuts, especially during long-distance cargo shipments. Improper moisture control during storage and transport can significantly increase the risk of fungal growth, leading to elevated aflatoxin levels and potential rejection at destination ports.

They are toxic compounds produced by certain molds, particularly Aspergillus flavus and Aspergillus parasiticus. These molds thrive in warm, humid conditions, making peanuts—rich in oil and stored for long periods—especially vulnerable.

Critical Thresholds:

Safe Moisture Content for Peanuts: Below 7%

Critical Relative Humidity: Above 65% promotes mold growth

Temperature Range Favoring Mold: 25°C to 35°C (77°F to 95°F)

Different countries impose strict maximum residue limits (MRLs) for aflatoxins in peanuts:

European Union: Maximum 2 ppb (parts per billion) for Aflatoxin B1 and 4 ppb for total aflatoxins.

United States: Maximum 20 ppb for total aflatoxins.

China: Maximum 20 ppb total.

India: Maximum 30 ppb total for exports.

Exporters must ensure their peanut shipments comply with the destination country's MRLs to avoid rejection, penalties, or bans.

For peanut exporters, managing aflatoxin levels is not just about product quality—it's about maintaining market access and protecting public health.

During export, moisture content has a significant impact on peanut quality and safety. Managing moisture levels presents several challenges that can impact both the marketability and compliance with international standards.

Effective moisture control is essential to preserving the safety and quality of peanuts during export. Cargo desiccant bags offer a dependable and effective way to handle moisture-related problems during transportation.

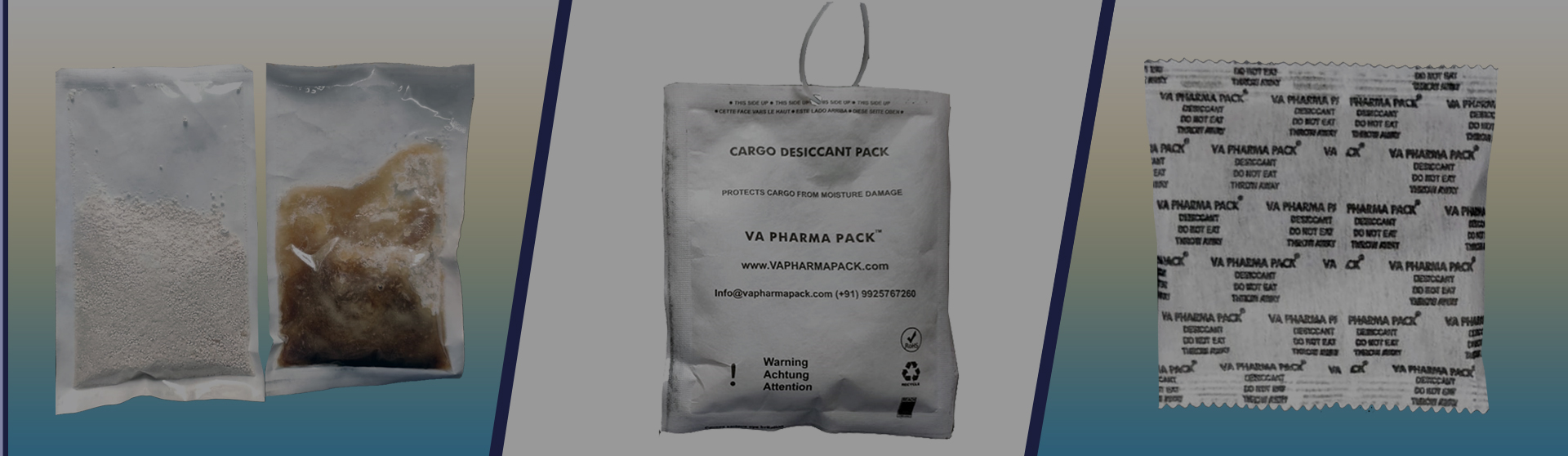

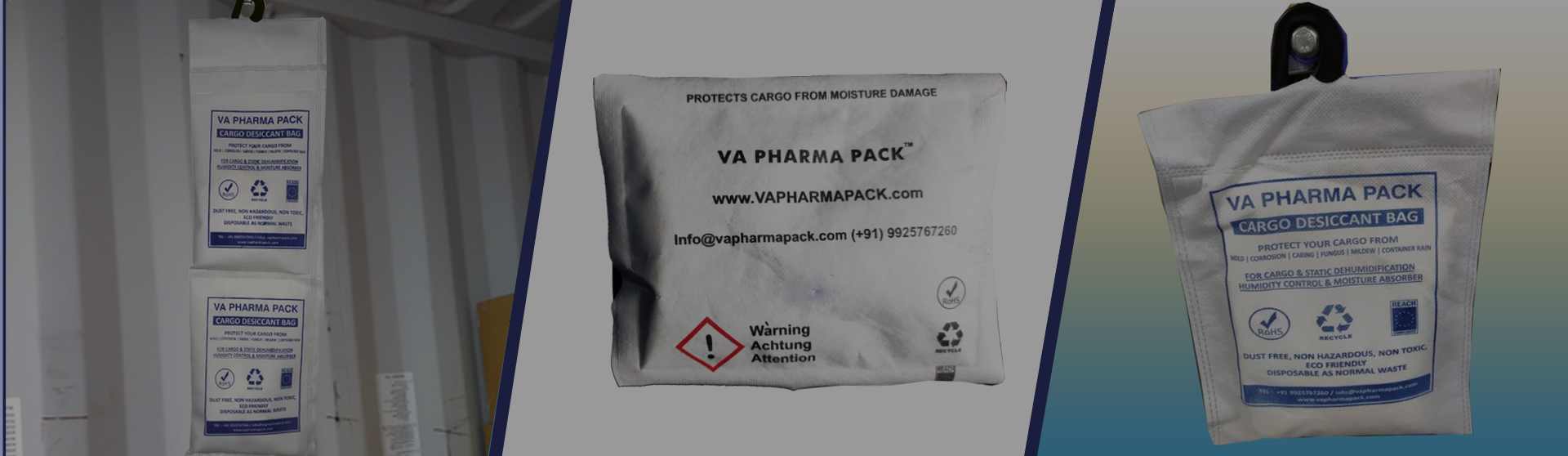

The cargo desiccant bag serves as a comprehensive solution for protecting peanut shipments from moisture-related damage by effectively controlling humidity inside the container. Desiccant bag for peanut export, significantly reduce the risk of spoilage, sogginess, insect infestation, and rancidity.

To safeguard peanuts from these export challenges, placing a cargo desiccant bag inside the container helps maintain a dry environment throughout the journey. Designed for ease of use, cargo desiccant bags can be hung or attached within the container for optimal moisture absorption. More than 250% of its weight in moisture and water vapor can be absorbed by each unit.

This cost-effective moisture control solution is ideal for preserving the quality of peanuts and other oilseed products during international shipping, minimizing potential losses and ensuring product integrity upon arrival.

Container Cargo Adsorbent is a unique product designed specifically for shipping & transportation industry.

Survey No.346/P, At. & Post : Raniya,

Before Omori India Pvt. Ltd.,

Savli, Vadodara,

Gujarat-391780, India.

+91 992 576 7260

Copyright © VA Pharma Pack. All Rights Reserved | Website Designed & Seo by Dhavat Infotech Pvt. Ltd.