Moisture is a critical risk factor in automotive glass shipment. Moisture buildup inside cargo containers poses a significant threat to automotive glass during shipping. Fluctuating environmental conditions, combined with limited airflow in sealed containers, create the perfect environment for condensation and humidity-related damage. Proper mitigation strategies are essential to maintain the integrity of automotive glass in transit.

Why is moisture control required for automotive glass shipment?

-

Condensation and Fogging:

During shipping of automotive glass, when cargo containers are exposed to varying external temperatures, the internal environment often experiences condensation—commonly referred to as “container rain”. When the humid air within the container cools and condenses on surfaces of automotive glass, this phenomenon happens. Resulting fogging and water stains can diminish the appearance of the glass and require reprocessing upon arrival.

-

Mold and Mildew Growth:

Sustained humidity inside a sealed container creates favourable conditions for mold and mildew during automotive glass exports. These contaminants often appear on packaging materials, rubber seals, or any organic matter present in the shipment. Mold not only presents a hygiene concern but can also lead to unpleasant odors and product degradation.

-

Corrosion of Integrated Components:

Automotive glass components may include metal brackets, heating elements, or sensor housings. During the shipment of automotive glass, exposure to moisture increases the risk of corrosion and malfunction, reducing the reliability of the product.

-

Packaging Integrity Loss:

Moisture absorption by cardboard, foam, or wooden crates can weaken structural packaging during automotive glass shipment. Weakened packaging fails to provide necessary support and protection, increasing the likelihood of mechanical damage during transport and handling.

What are the best solutions to protect automotive glass exports from moisture damage?

Protecting Automotive Glass during Exports from Moisture-Related Damage

Automotive glass is highly sensitive to environmental changes during transit. Long-distance shipping often involves fluctuating temperatures and sealed container environments that increase the risk of moisture buildup. Without proper humidity control, automotive glass products can suffer from condensation, corrosion, mold, or packaging degradation.

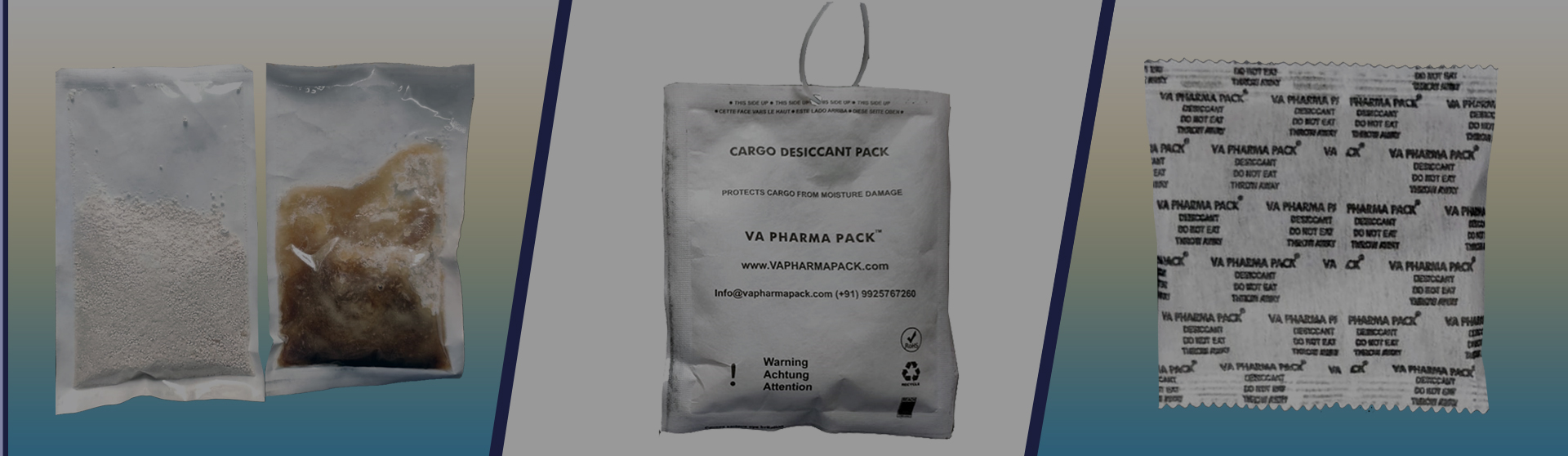

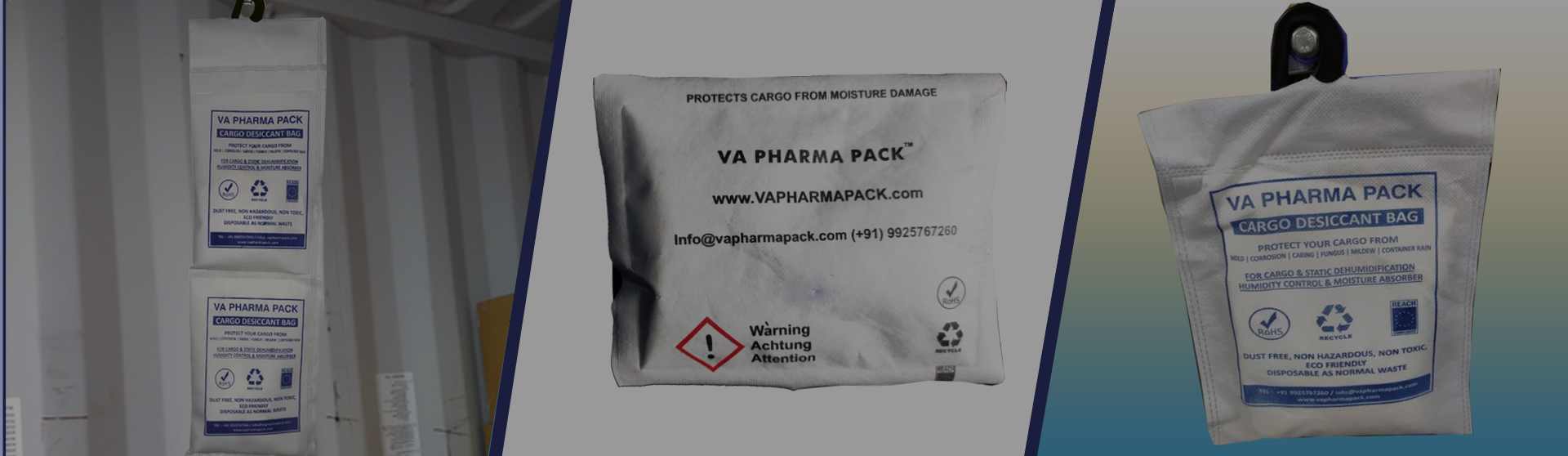

Cargo desiccant bags offer an effective and reliable method for mitigating these risks by maintaining a stable, dry environment inside transport containers during automotive glass shipment.

Key Benefits of Cargo Desiccant Bags in Automotive Glass Shipment

-

Effective Moisture Absorption: Cargo desiccant bags are formulated to absorb and retain moisture from the surrounding air, reducing relative humidity inside enclosed containers during automotive glass shipments. Cargo desiccant bags help prevent the formation of condensation on automotive glass surfaces and embedded components.

-

Prevention of Fogging and Water Spots: Temperature fluctuations commonly cause fogging or water spots on automotive glass surfaces during shipment. Cargo desiccant bags help eliminate the conditions that lead to these visual defects, preserving the appearance and clarity of automotive glass throughout the shipment.

-

Corrosion Protection for Integrated Components:

Modern automotive glass often includes metallic elements such as brackets, connectors, and heating grids. Moisture exposure can lead to corrosion and oxidation in these parts, potentially affecting functionality. Cargo desiccant bags lower this risk by managing the surrounding humidity.

-

Reduction in Mold and Mildew Formation: Mold and mildew can develop in damp conditions, especially on rubber seals or packaging foam used in automotive glass shipments. By maintaining a dry environment, cargo desiccant bags help prevent biological contamination that could compromise product quality.

-

Packaging Integrity Preservation:

Packaging materials such as cardboard, foam inserts, and wooden crates can degrade when exposed to moisture. Cargo desiccant bags help preserve the strength and shape of these materials, ensuring continued protection of the automotive glass items during transit.

-

Long-Lasting Effectiveness in Varying Climates:

Cargo desiccant bags are engineered to perform consistently across a wide range of climates and transit durations during automotive glass transit. Cargo desiccant bags' high absorption capacity and durable construction make them suitable for both short-haul and long-haul shipments.

-

Simple Implementation and Passive Functionality:

No power, maintenance, or monitoring is required for cargo desiccant bags to function effectively during automotive glass shipment. Once deployed inside a container, these units begin absorbing moisture immediately and continue operating throughout the journey.

Why Use Cargo Desiccant Bags for Exporting Automotive Glass?

Moisture Protection: A Critical Requirement for Automotive Glass Automotive glass is highly sensitive to environmental conditions during transport. Fluctuating temperatures, sealed container environments, and prolonged shipping durations often lead to the accumulation of moisture inside cargo containers. During automotive glass export, without adequate protection, this moisture can cause condensation, corrosion, mold growth, and packaging failure—posing serious risks to product quality and customer satisfaction.

Cargo desiccant bags provide a dependable and efficient solution for controlling humidity during automotive glass export, helping to prevent moisture-related damage throughout the shipping process.

-

Moisture Protection:

During automotive glass shipment, cargo desiccant bags are designed to absorb excess moisture within shipping containers, effectively reducing relative humidity. This environment prevents condensation, commonly known as "container rain", which can cause rust, corrosion, and mould growth on automotive glass surfaces.

-

Long-Term Efficacy:

High-performance cargo desiccant bags can absorb moisture up to three times their weight, providing continuous protection for extended periods. This prolonged efficacy is crucial for long-distance shipments.

-

Non-Toxic and Environmentally Friendly:

Cargo desiccant bags are eco-friendly desiccants for automotive glass shipping and are also non-toxic, free from harmful chemicals, and compliant with environmental standards. Cargo desiccant bags are safe for the environment because they are authorized by the USFDA and may be thrown away with regular trash.

-

Ease of Use:

Cargo desiccant bags are straightforward to implement in automotive glass shipment. They can be suspended inside containers or placed within packaging, requiring minimal handling. Their design ensures that absorbed moisture is contained in a gel form, eliminating the risk of leakage or spoilage.

-

Cost-Effective Solution:

Utilising cargo desiccant bags can reduce the incidence of product damage, returns, and insurance claims, leading to cost savings. Cargo desiccant bags' affordability and effectiveness make them a valuable investment for exporters aiming to maintain product integrity and customer satisfaction.