Humidity plays a crucial role in the performance and durability of corrugated packaging, particularly during international and long-distance shipments. As global trade expands across diverse climates and transport conditions, understanding the impact of moisture on corrugated boxes is essential for maintaining shipment integrity and minimizing damage risks.

Corrugated fiberboard, composed primarily of paper, is inherently hygroscopic—meaning it readily absorbs moisture from the surrounding environment. Exposure to high humidity levels can compromise the strength and shape of packaging materials, directly affecting product protection during transit.

Effective humidity management is essential for preserving the structural integrity and performance of corrugated box packaging during export. Recognizing and mitigating moisture-related risks can contribute significantly to reducing product damage, enhancing supply chain reliability, and supporting regulatory compliance across global trade routes.

When corrugated boxes are exposed to elevated humidity, they can lose a significant portion of their load-bearing capacity during shipment. This reduction in strength increases the likelihood of crushing or collapsing, particularly in stacked pallet configurations.

Fluctuating moisture levels may lead to warping or softening of the corrugated box structure during export. Deformed boxes can disrupt stacking, increase pallet instability, and lead to operational inefficiencies during loading and unloading.

During corrugated box shipment in ocean containers, rapid temperature changes can cause condensation on container walls—known as "container rain." Dripping moisture may directly impact the boxes, even if not exposed to external weather.

Persistent moisture exposure creates favorable conditions for mold growth during corrugated box shipment. This poses quality concerns for goods like paper and packaging materials.

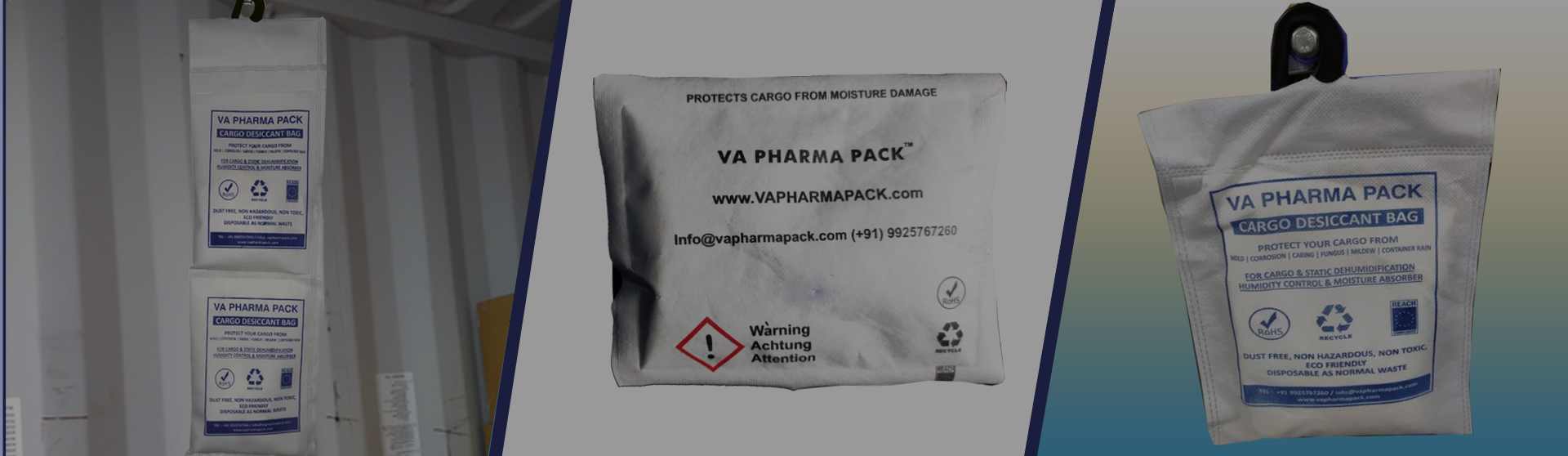

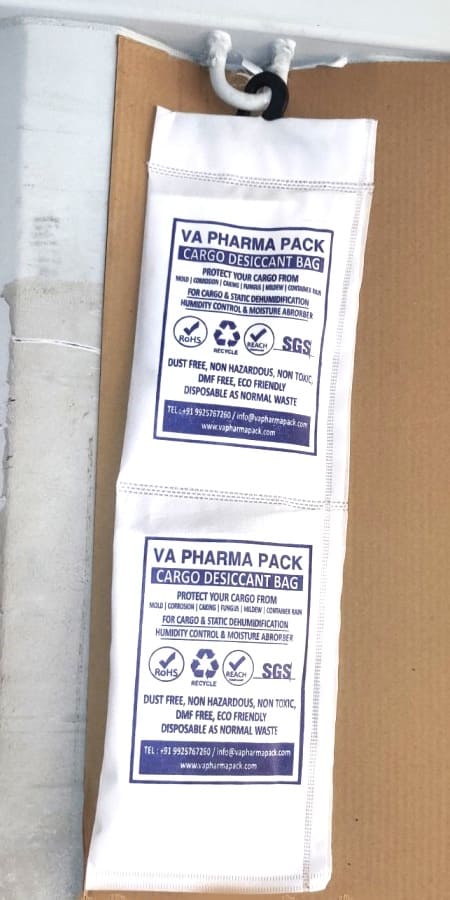

Cargo desiccant bag is a simple, effective solution for preserving the integrity of corrugated box exports. By reducing humidity and preventing moisture damage, it plays a vital role in maintaining product quality and minimizing losses across international supply chains.

Moisture-related damage remains a significant concern in the shipping of corrugated boxes, particularly during long-distance transport or storage in humid environments. Cargo desiccant bags provide an efficient and dependable method to protect packaging and contents from the harmful effects of excess humidity.

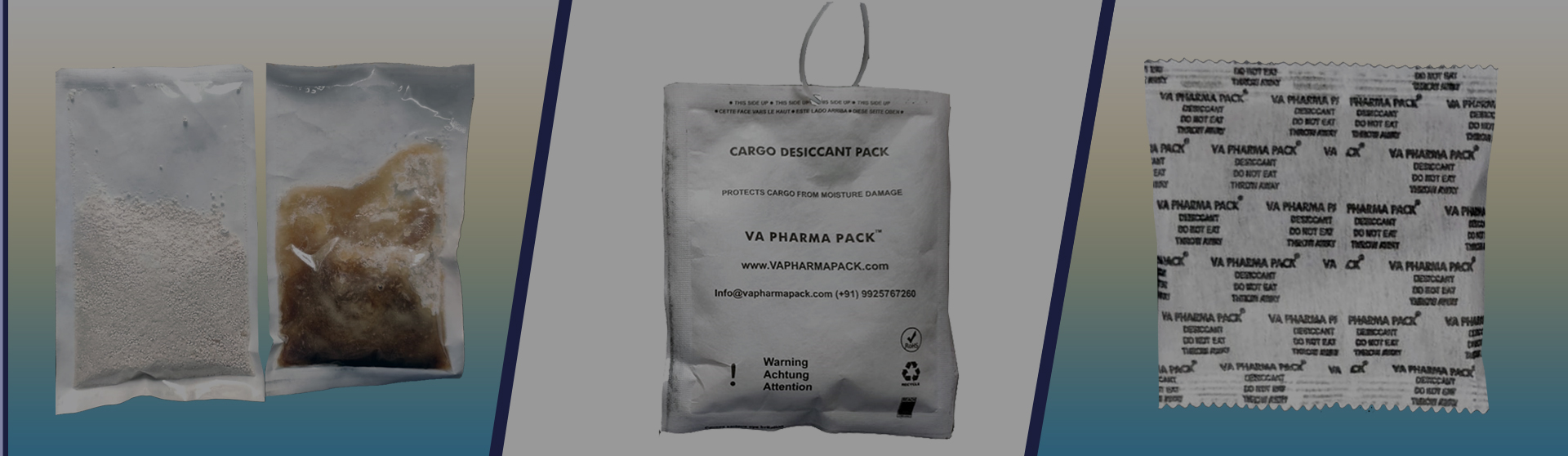

The cargo desiccant bag serves as a comprehensive solution for protecting corrugated boxes from moisture-related damage by effectively controlling humidity inside the container. Corrugated box protection from moisture is essential during long-distance shipping. Cargo desiccant bags significantly reduce the risk of warping, mold growth, and weakening of structural integrity, and surface damage during exports To safeguard corrugated boxes during transit, placing a cargo desiccant bag inside the container helps maintain a dry environment throughout the journey. Designed for ease of use, cargo desiccant bags can be hung or attached within the container for optimal moisture absorption. Each unit can absorb more than 250% of its weight in moisture and water vapor. This cost-effective moisture control solution is ideal for preserving the quality and strength of corrugated packaging during international shipping, minimizing potential losses and ensuring product integrity upon arrival.

Container Cargo Adsorbent is a unique product designed specifically for shipping & transportation industry.

Survey No.346/P, At. & Post : Raniya,

Before Omori India Pvt. Ltd.,

Savli, Vadodara,

Gujarat-391780, India.

+91 992 576 7260

Copyright © VA Pharma Pack. All Rights Reserved | Website Designed & Seo by Dhavat Infotech Pvt. Ltd.